Rivian Internal native app

Factory End Of Line Tool (EOL)

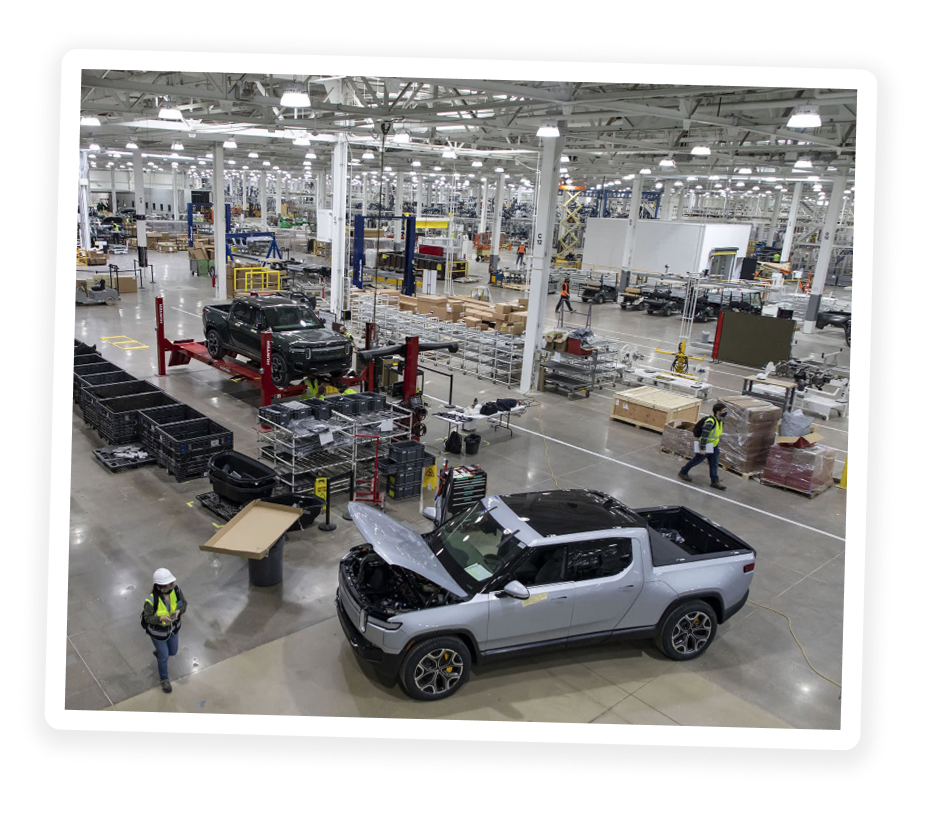

At Rivian, I led the design of the factory application allowing technicians and leads to complete tasks needed at the final steps of production such as final checks and calibrations. Vehicle management after the production line was poor causing low factory output. The pressure was high - We were pre-IPO and customers had been waiting for ~3 years for their vehicle after pre-ordering. Additionally, valuable data reflecting production issues and patterns, were not being captured effectively. This delayed the learning and adapting in real time of factory processes and pattern failures.

The Problem

Excessive time to complete Factory End of Line Tasks

Lack of information for uncompleted processes

Unreliable tracking of vehicle status and location in factory

No centralized data capture for issues or patterns identified

My Role and Responsibilities:

Lead Designer for internal native mobile application

Design advisor for the desktop counterpart

Researcher for in-factory processes and flows

Platform

iPad Pro - iOS

The Team:

1 Product Manager

1 Engineering Manager

3 Front End Devs

1 Back End Engineer

1 Lead Designer (Me)

My Approach

I coordinated with the team, users and other stakeholders to gather initial requirements to help provide guidance for an MVP. We worked with 8 Factory Technicians (4 Repair, 3 Inspection, 1 Shift Manager). We also worked the Director of Operations and the CEO.

Factory Visits

Gather Requirements

Assess Current Systems

Exploration and Proof of Concept

Factory Visits Learnings

I visited the factory to try to understand some basics:

Users and their responsibilities

Factory Requirements

Factory Layout and Processes

Pain Points and Opportunities

Factory layout (End of Line)

Work Order Status structure we had to work with

Initial Decisions We Made

The physical location and setting of the factory would dictate a lot of the UI decisions.

Status UI must be easily read from 2 meters distance

Adhere to AA - AAA WCAG 2.0 in color and type

Establish hierarchy of primary CTAs on screen

User needs to know where they are in the app at all times

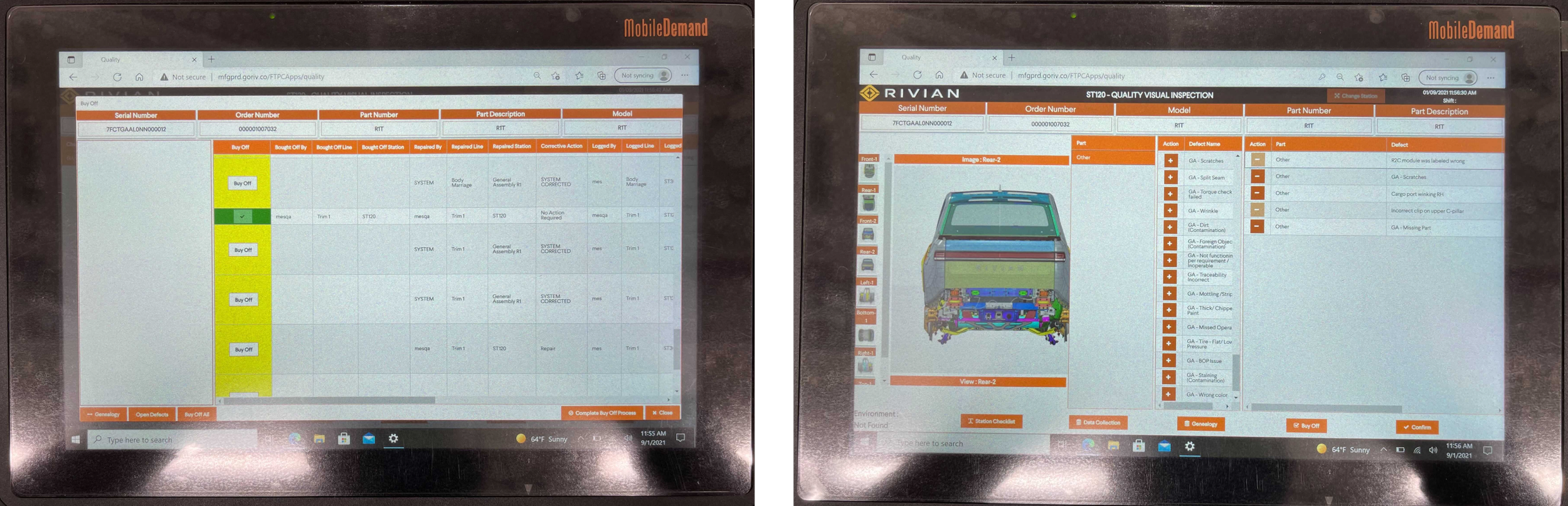

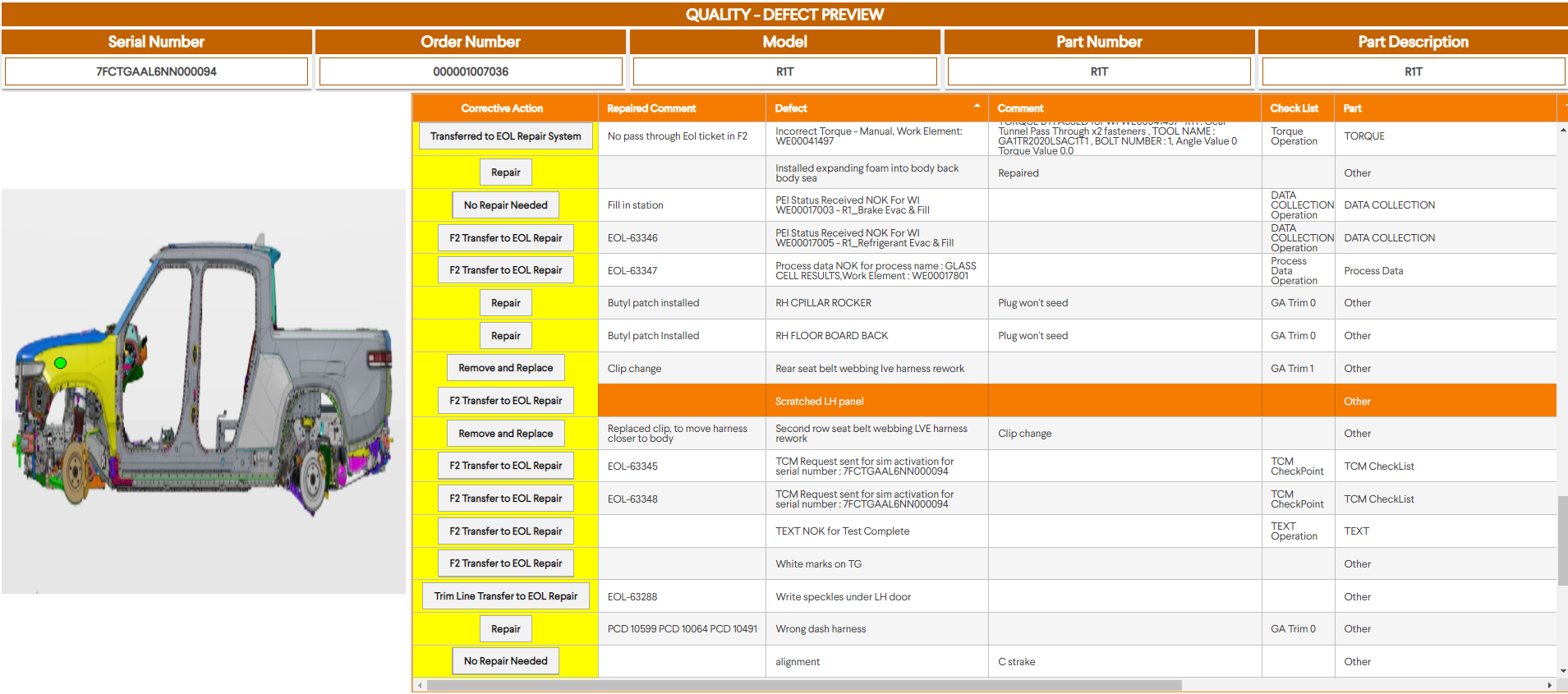

Assessing Current Systems

I learned what was being used in the industry and in our factory. One of the goals of this project was to align to the existing mobile application design. This meant identifying what worked well and what was “noise” in legacy systems. We found users experienced unnecessary friction when trying to navigate their workflows. Many times, there was no clear path to take in the UI.

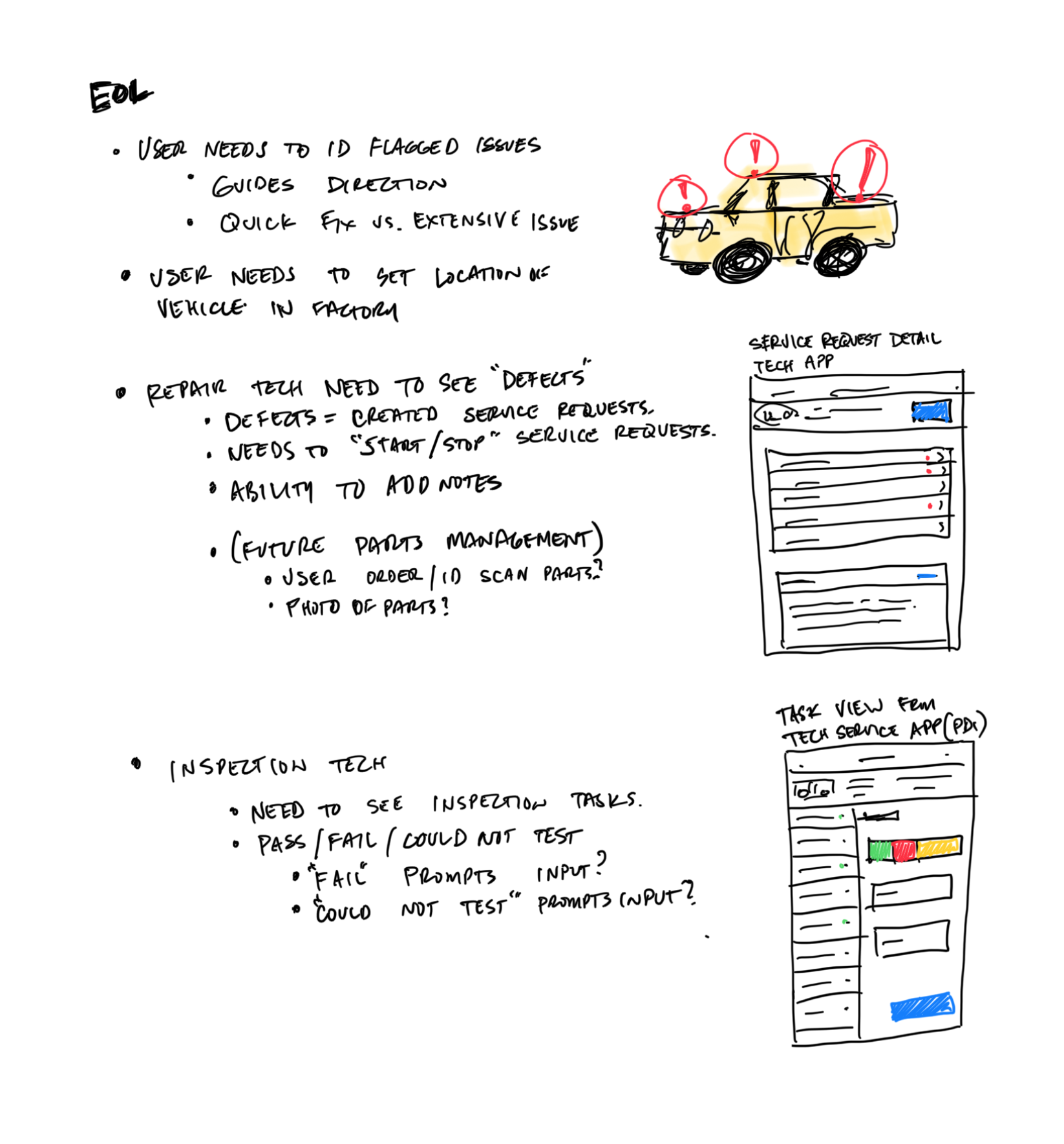

Exploration

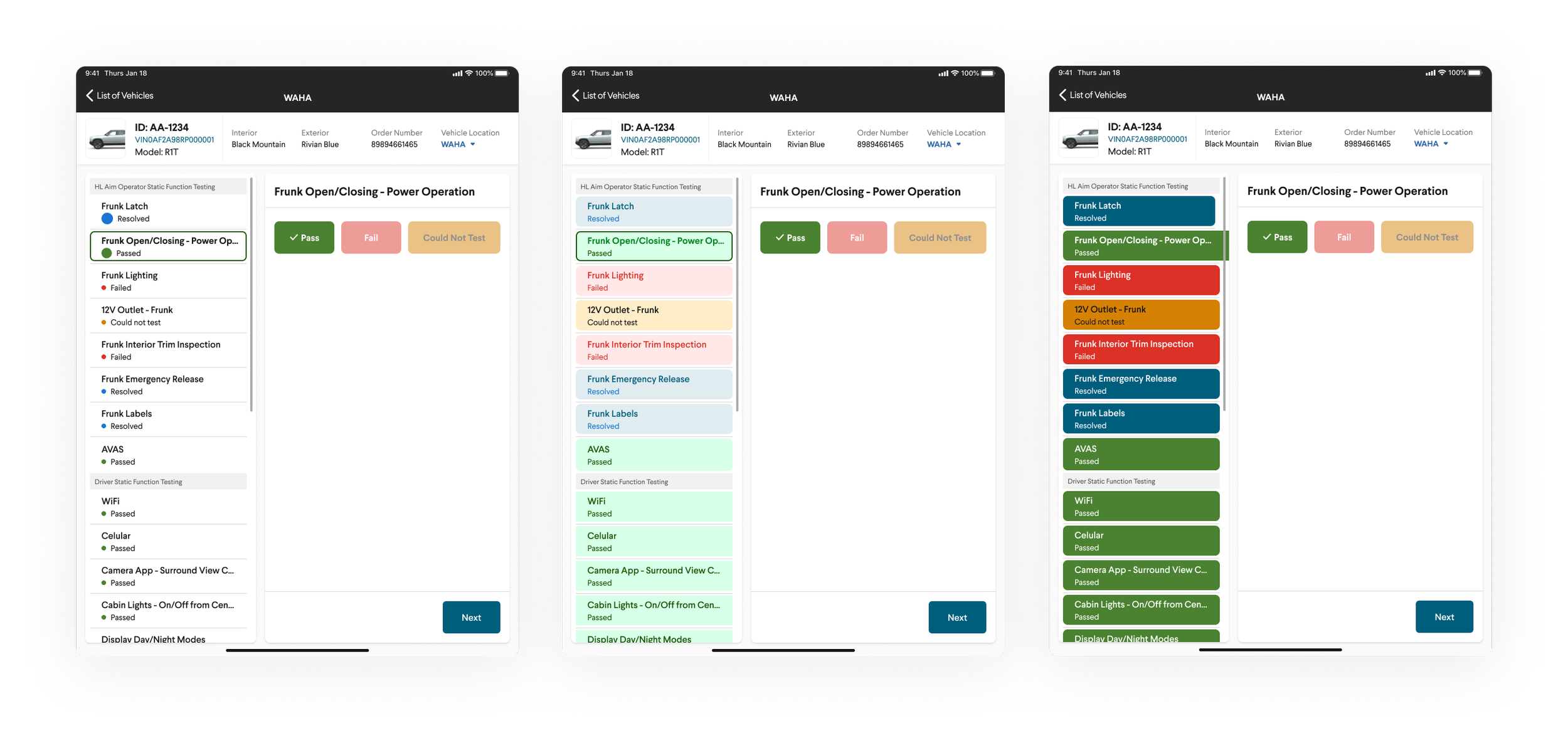

Considering the application would be used on an iPad Pro, I started sketching and exploring UI options for the main use cases and screens we planned to launch in the application. I started with some of the more challenging status display screens.

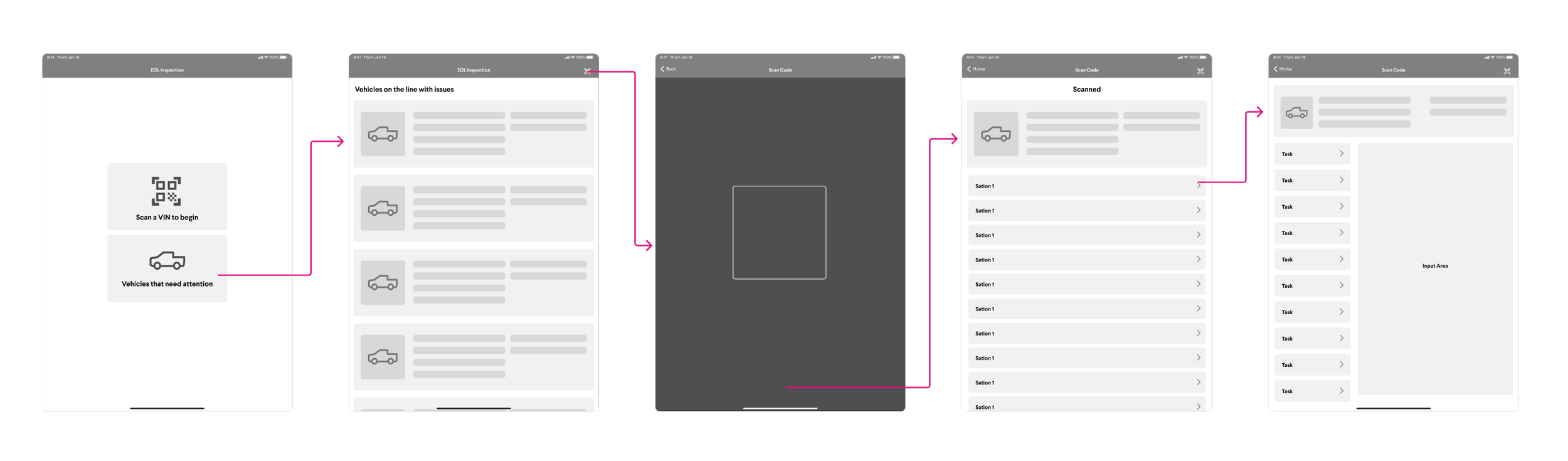

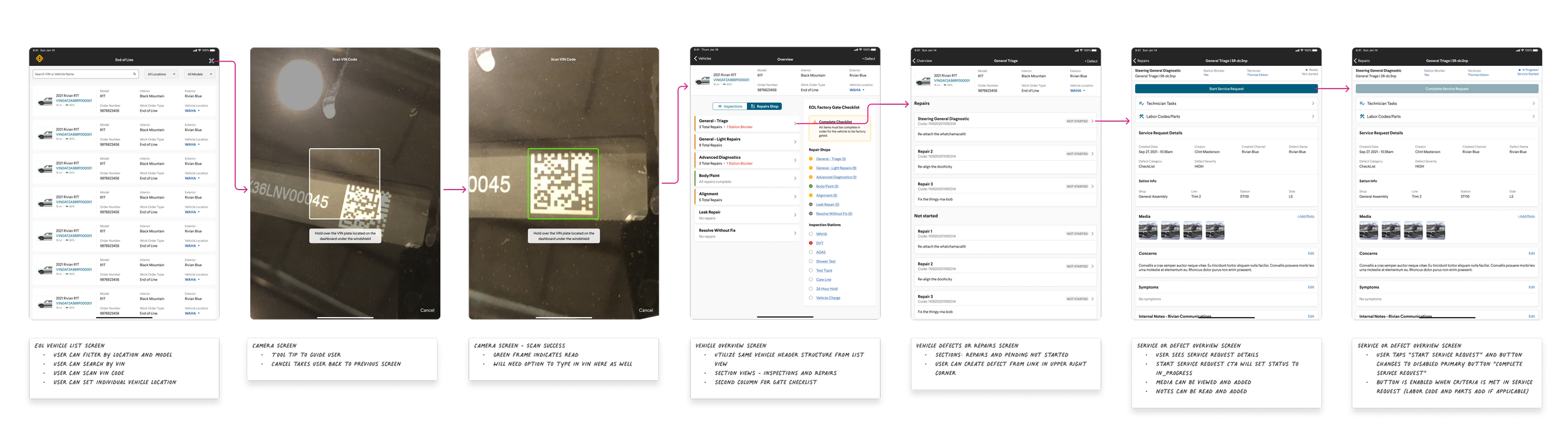

Proof of Concept

After initial sketches and mocks, I created prototypes to communicate the key flows we were defining for MVP. Being able to “tap” through flows helped identify gaps and edge cases. It was critical step for stakeholder buy-in and defining a MVP.

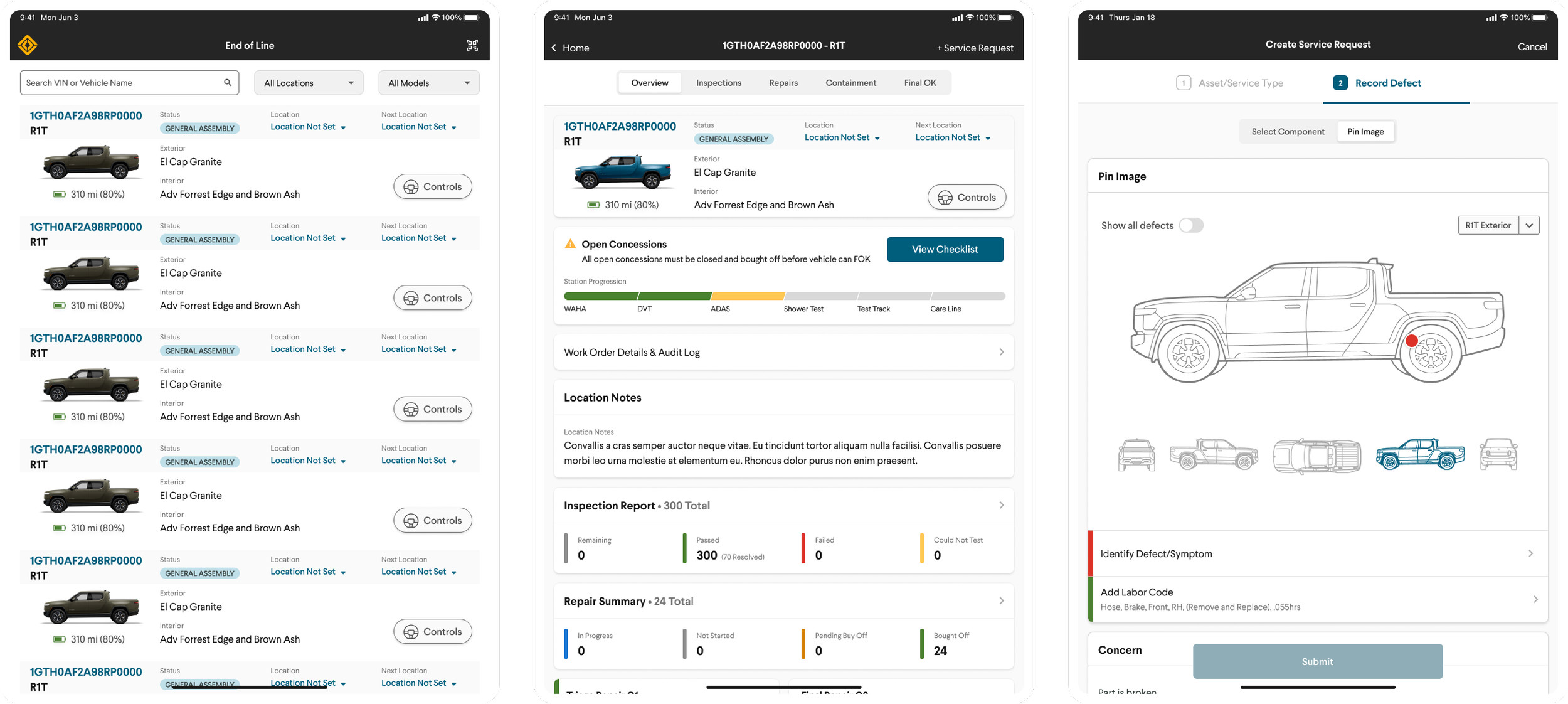

A list of vehicles - Work Order auto-generated in production

Display inspection and repair station status

Allow user to input task outcome and notes

Vehicle location management

Scan VIN Data matrix code

Initial wireframes for engineering discussions

Proof of concept prototype

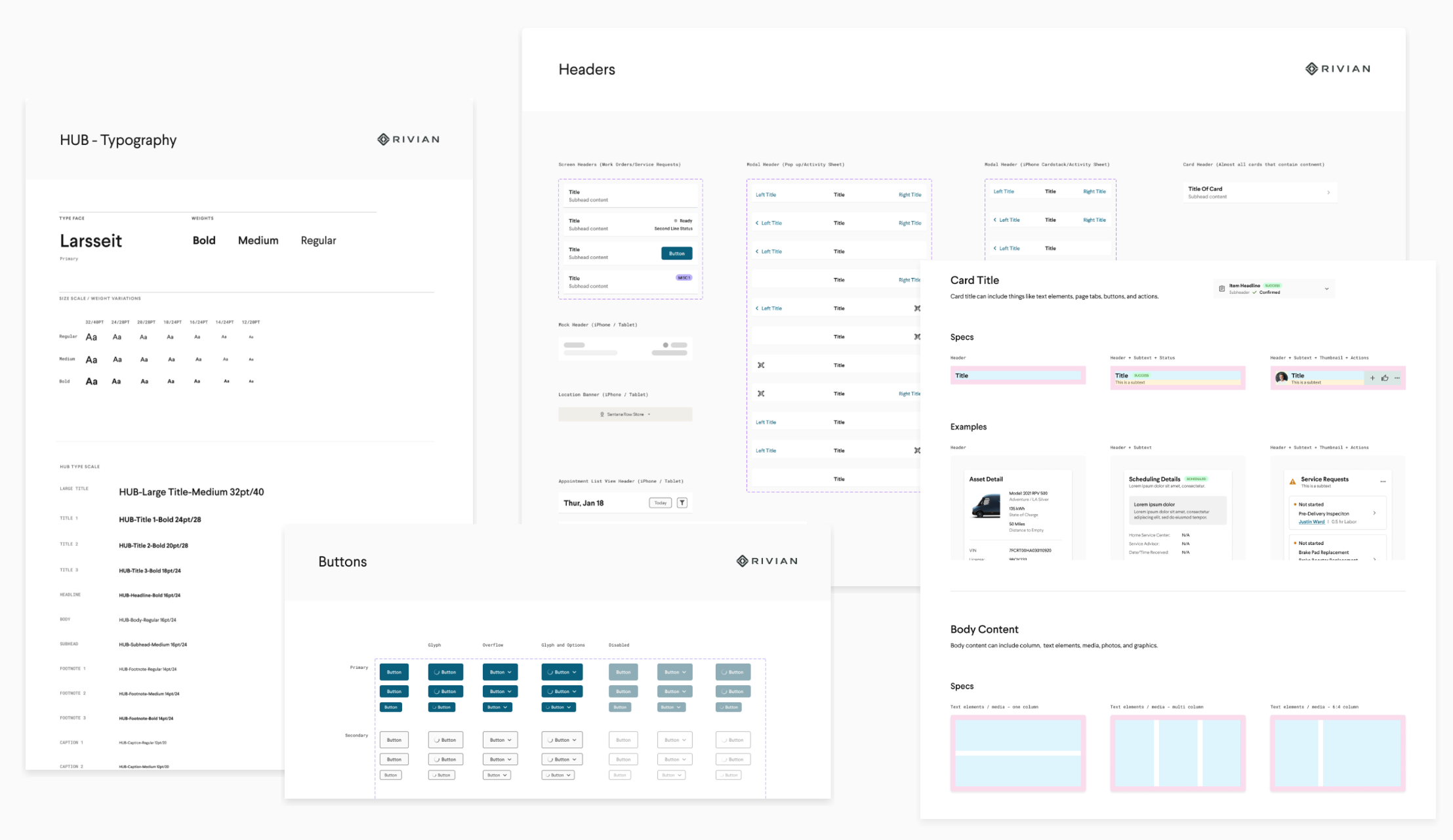

Leveraged Design System and Component Library

In a previous project, I created the mobile component library based on the Rivian Design System (RivanOS). I worked with the engineers to structure the components, ensuring we remained aligned.

Engineer Hand Off

Being that the communication with engineering and product was intimate on this project, there were no surprises during hand off.

Shared component library with defined patterns

Dedicated Page in master file for each design associated with JIRA ticket.

Clickable prototypes

All image assets formatted

Example of a hand-off page in Figma

Launch and Measure

We monitored some key metrics for the launch of the application.

Number of completed inspection tasks

Number of corrected defects

Frequency of signed-off vehicles

Quality of data captured

Basic user behavior

Results at the End of Week One

We closely monitored usage and found promising metrics!

Tasks Completed

Increasing exponentially

Corrected Defects

Expected to increase, then decrease as production improves

Factory OK Frequency

Increasing by a factor of 4 at the end of 3 weeks

Quality of Data Collection

Some of which was used to power diagnostic efforts at service centers

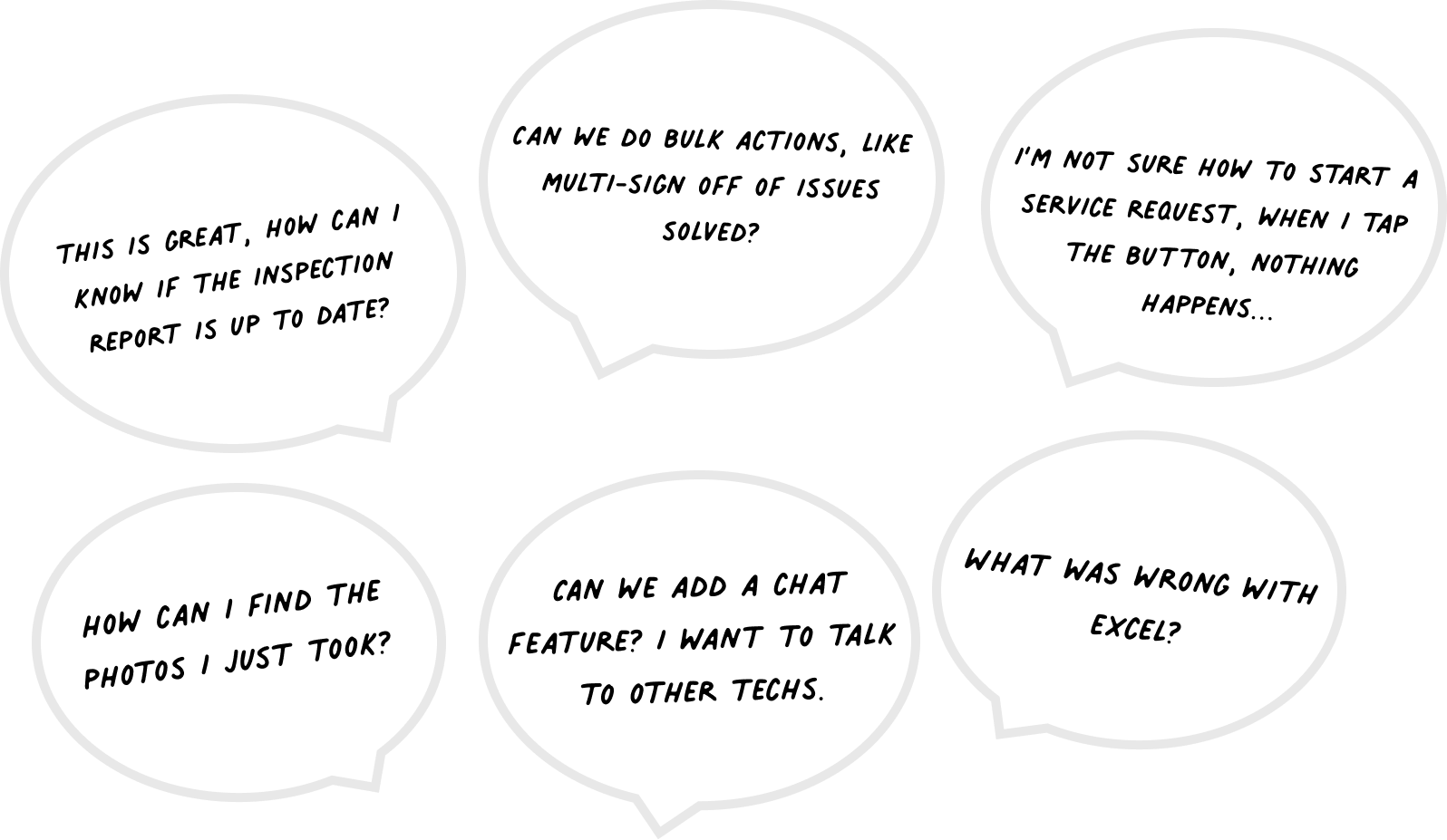

There Was Feedback

We gathered feedback and adjusted the strategy where needed.

We Began to Implement Updates

After assessing feedback and usage metrics, I updated some of the designs and began to roll them out.

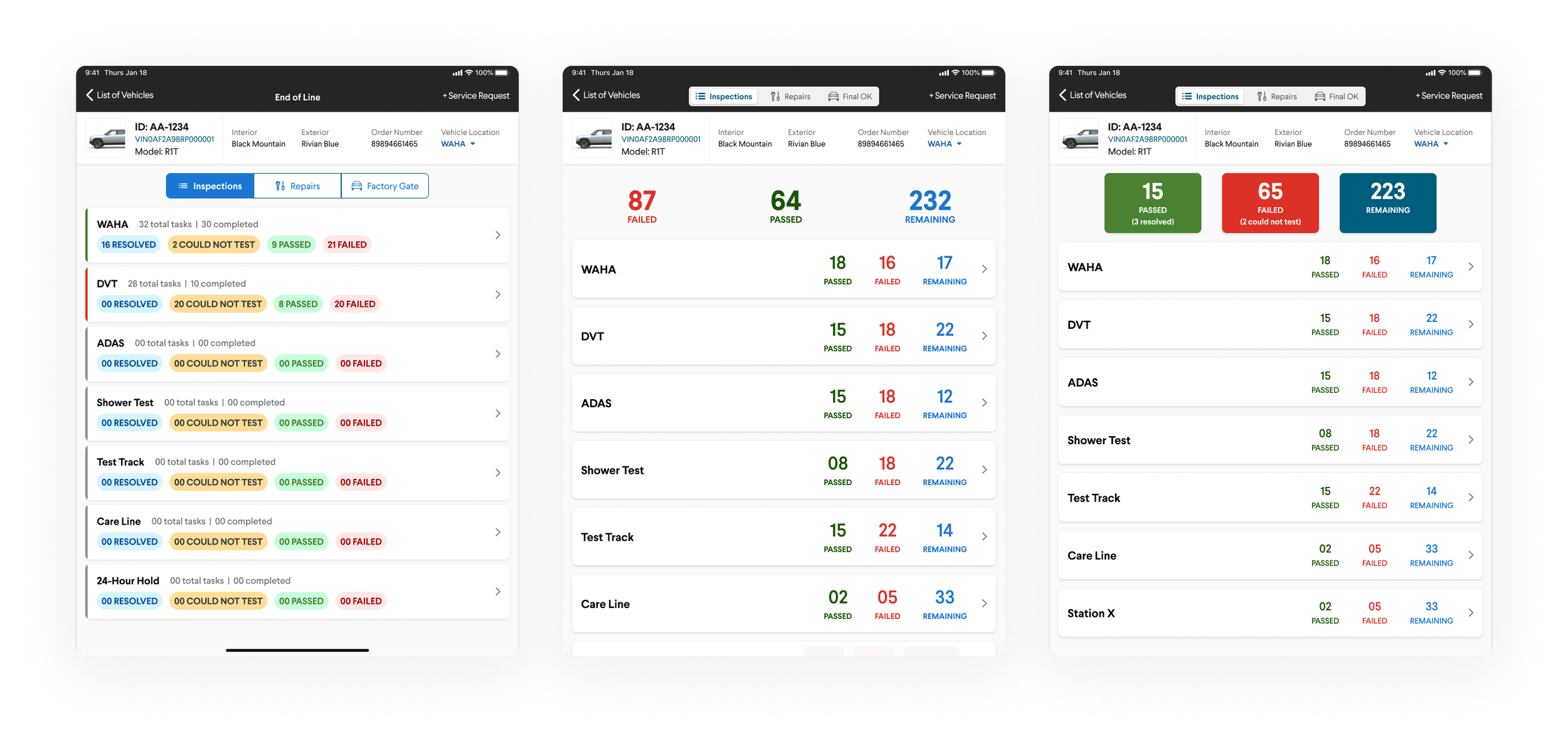

Introduced a jump off screen to help guide technicians to their specific workflow faster.

Updated vehicle list screen with new information hierarchy and the addition of vehicle control access

Updated vehicle detail screen with clear at-a-glance status information and an intuitive navigation structure

Updated designs for key screens after feedback and metrics analysis

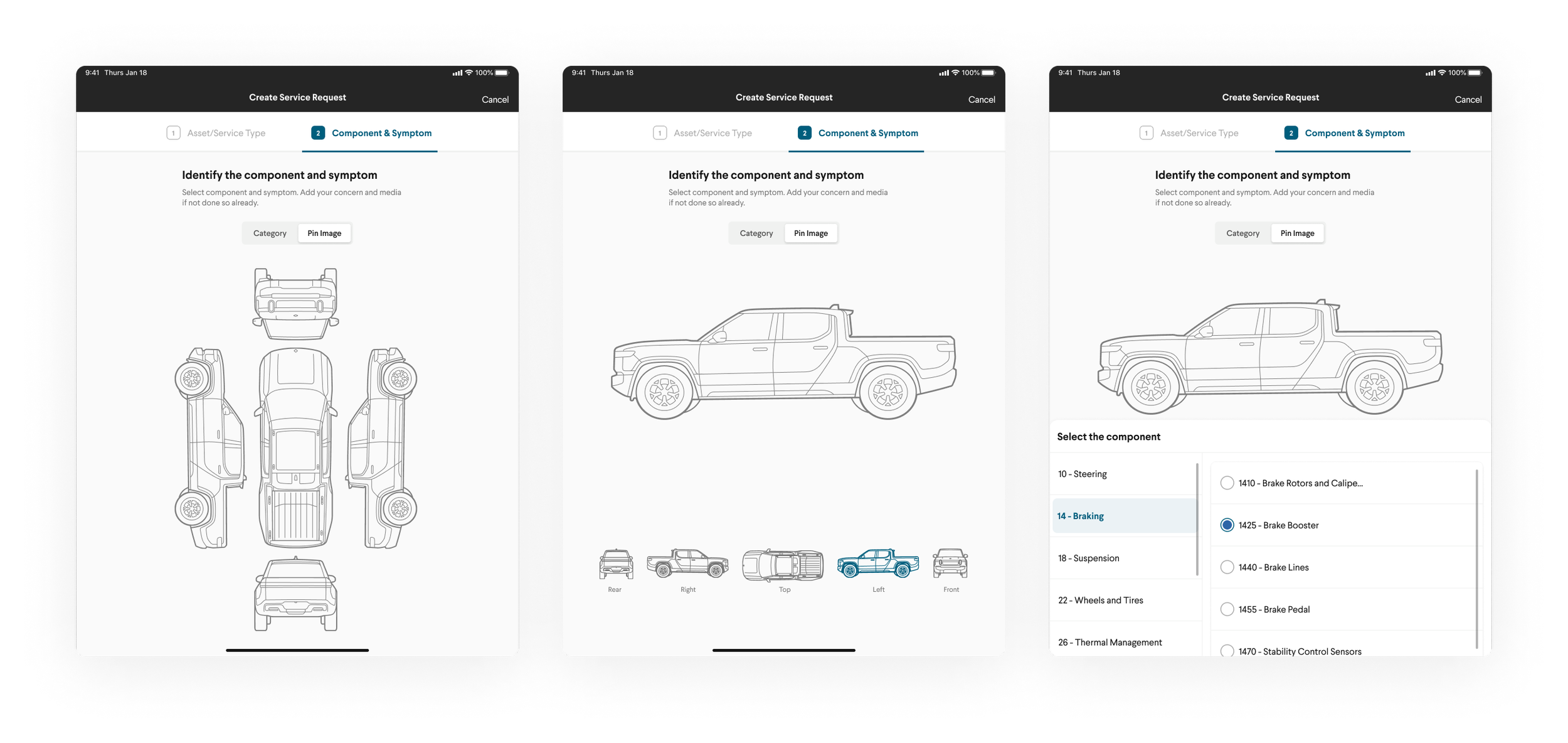

New Features Designed and Launched

We began to introduce new features such as a defect capturing system that I designed. This system replaced a highly un-trackable whiteboard system they were using in the factory. The UI allowed users to “add a pin” to the area of defect, provide context for the defect identified, then create a subsequent Work Order to add the issue to a queue of work. We ended up making this feature accessible in almost all parts of the application.

Outcome

Overall, the application had a huge impact on the company - the timing was especially significant. We were pre-IPO and customers were starting to lose faith in their pre-order status. This application helped greatly increase the speed and quality of production of the first vehicles produced at the factory.